After many years working mainly in the Leeds area, Walter Bevan Harris, a qualified leather technician and leather chemist, with the help of a group of employees, chose to start his own business in 1955.

After many years working mainly in the Leeds area, Walter Bevan Harris, a qualified leather technician and leather chemist, with the help of a group of employees, chose to start his own business in 1955.

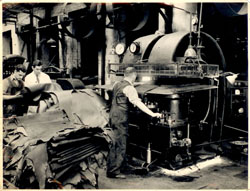

He rented premises in Leeds Road, Otley (a building which had been trading as a tannery) and Bevan Harris Ltd was created.

The principal product made was industrial gloving from split shoulders and butts. They quickly added suede production for the bootee, slipper and sports shoe trade.

In the early 1960’s both his sons, Ian and Roger Harris, joined the company and shortly after, with lease difficulties, a new site was needed.

The present site at Broadlie Works, Neilston was acquired in 1963. The premises, formerly a bleach mill dating back to 1792, had been converted to a split leather tannery in 1947 (The Clyde Leather Co Ltd), partly due to the ready supply of soft water for dyeing and tanning.

This enterprise, now known as the Clyde Leather Company, grew rapidly, notwithstanding the premature death of Walter Bevan Harris in August 1967, leaving Ian and Roger to manage the business.

The products ranged from industrial gloving, suede splits and pigmented printed splits. All three products thrived due to consistent high quality and keen pricing. The finished splits became the principal product, supplying all the leading football boot and training shoe manufacturers.

In the late 1980’s, Ian’s two sons, Paul and Richard joined the family business. Paul has a financial background, working and training in London and oversees the subsidiary companies Clyde Marine Leather and R C Brady (UK) Ltd. Richard as the Managing Director of the Clyde Leather Company, has extensive experience from working in Southern Hemisphere tanneries and also studied at the British School of Leather, Northampton University where he gained a degree in Leather Chemistry.

The British leather industry was, at that time, generally in a very poor state many of Clyde Leather’s core customers shut their shoe factories in large numbers, but through hard work, downsizing and diversification the company survived.

Present Day

Today the tannery, under the leadership of Richard Harris, still produces suede/pigmented and industrial leathers. However, the company now tailor-makes every customers’ requirements to produce a bespoke product worthy of our continued existence within the British Leather Industry.

We are the only suede tannery in Scotland.Despite being a third generation company Clyde Leather Company is young, in terms of age of the Industry, with huge enthusiasm for developing and improving the quality of their leathers.

The raw material used are splits and are sourced within the UK for quality assurance and the Clyde Leather Company remain fully compliant with REACH regulations.

We have an enthusiastic and dynamic workforce with a strong focus on quality throughout the process and up to the finished product. The implementation of new machinery and infrastructure enables Clyde Leather to keep in step with the latest techniques.

We have qualified technicians developing leathers with a very hands-on approach to ensuring the desired results are achieved and this is continued through into the production process.

The future is promising: a full order book, plant investment and new products. Clyde Leather Company continues to flourish for another generation.